Home

> Gingery Drill Press

|

My Gingery Drill Press

|

I don't pay people to go to

fancy restaurants and eat great food for me. So why would I simply buy

a drill press rather than learn foundry skills by making my own

machine? The way I see it, this is a journey of learning that has a

nice drill press as a prize along the way.

|

|

My Foundry

|

I use a Gingery Charcoal

Furnace and a cast steel "lead pot" for my crucible. My tongs are

home made as are my flasks. Petrobond

is my casting sand.

|

|

The snow has been cleared back

to a safe distance. I am working over a 2" bed of dry sand. Any molten

aluminum that spills will hit the sand rather than contact the

relatively wet concrete which can explode. The muffin tin is large

enough to contain the entire contents of the crucible just in case a

flask experiences a failure.

|

|

|

Here is a close-up view of a

pour. At this time I had not made sheet metal spats to cover my boots.

They prevent molten aluminum that could spill from getting inside your

shoes. Ouch!

|

|

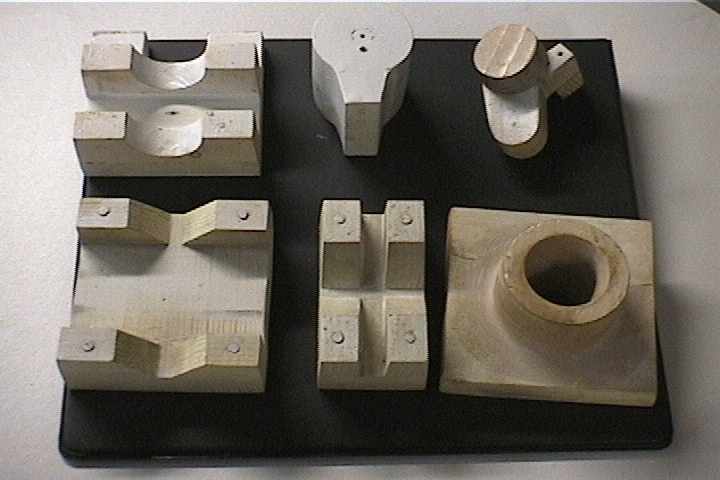

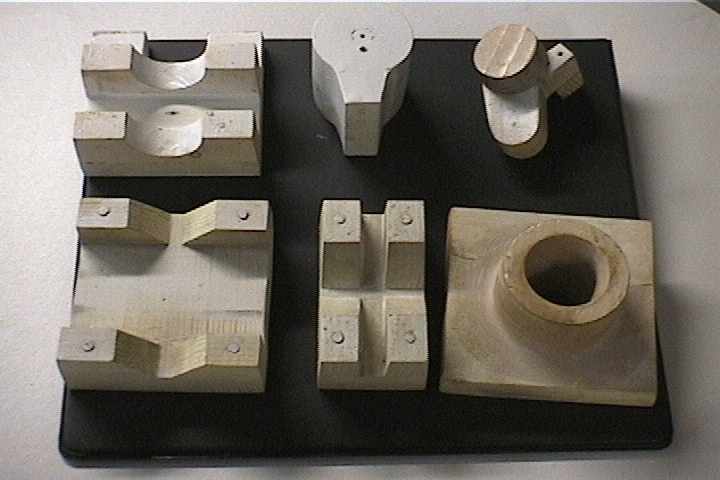

A Selection of Patterns

|

|

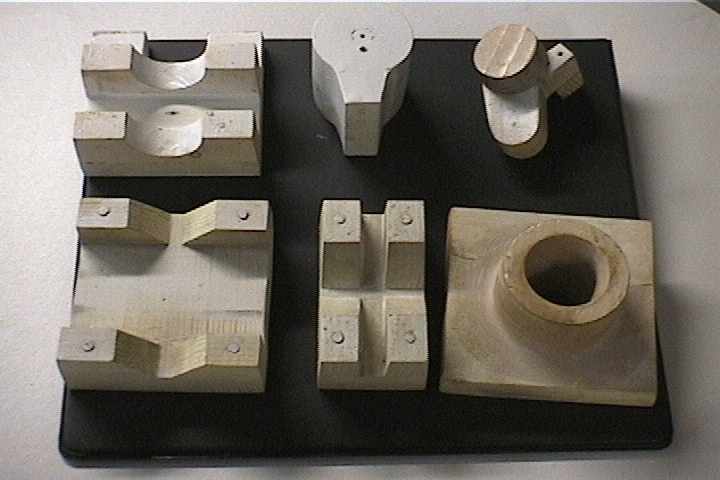

These patterns are made from

pine and Bondo with a surface coating of auto body primer.

|

|

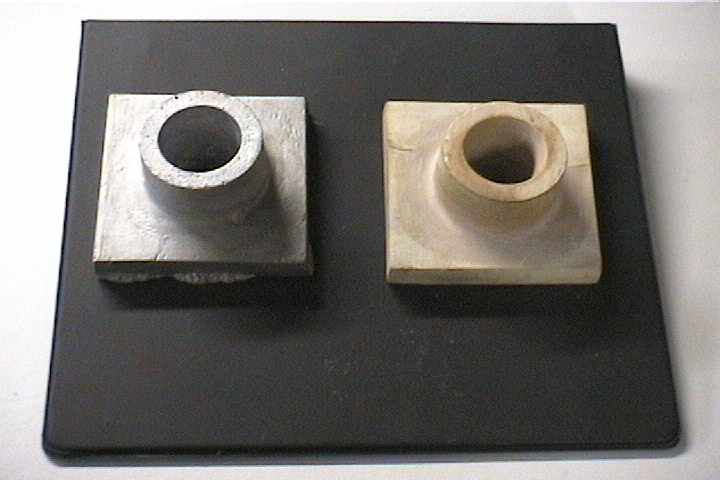

Drill Press Base Casting

|

|

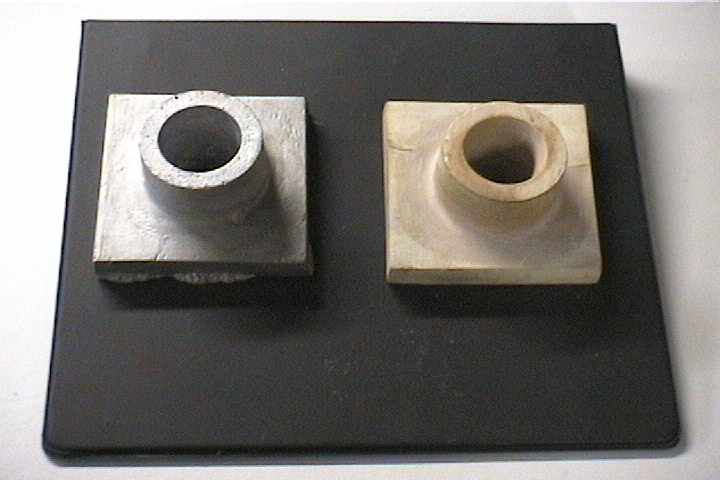

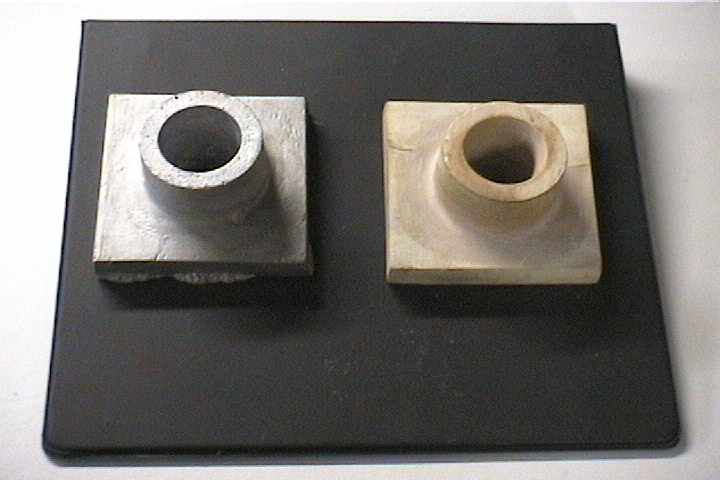

This was the last casting I did

using green sand (mostly sand, clay and water). The part is usable but

the finish leaves much to be desired. However, if you look

carefully, you will see defects in the surface of the pattern that are

accurately reproduced in the casting.

|

|

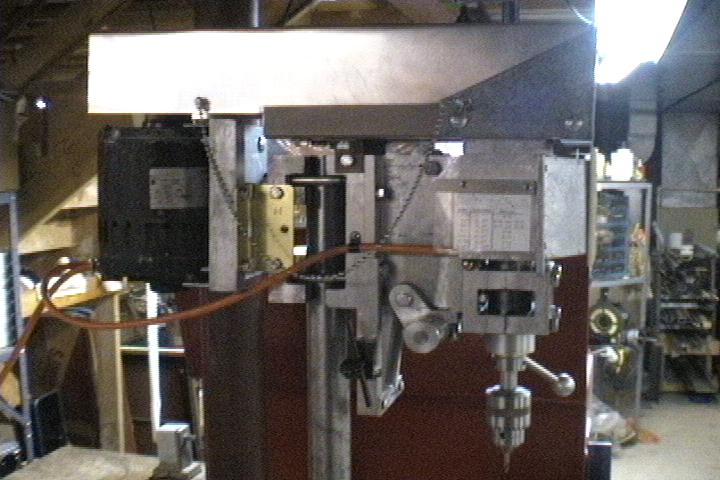

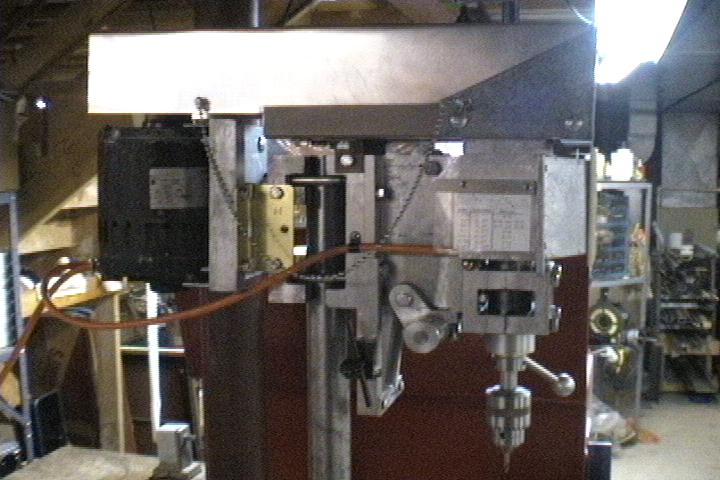

The Final Product

|

|

|

|

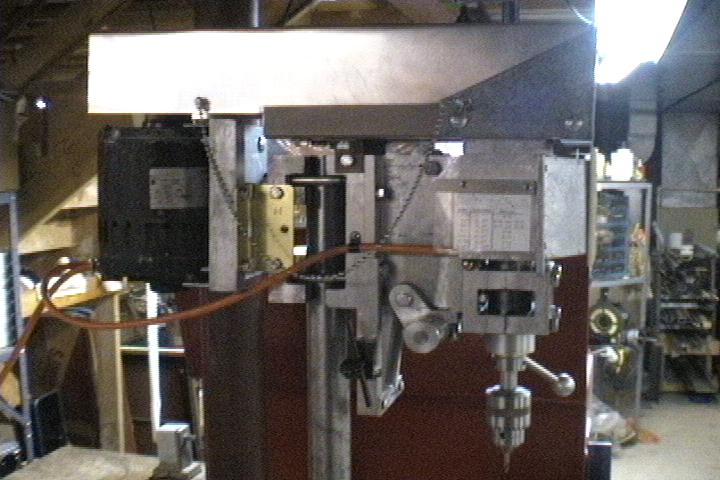

My sandbox can be seen on the

left side of the picture. I used the face plate from my lathe as a

pattern for the drill press table.

|

|

|

Remember that base casting? Here

it is installed. The column is a tight fit to the ID of the base. No

fasteners were needed to joint them.

|

|

Home >

top

|

last updated 01/15/2004

|