A reliable finger type Dial Test Indicator (DTI) can be an invaluable instrument. It can also lead you down the "garden path" if you are not careful. I will discuss the limitations of a DTI plus how to test it for accuracy.

A reliable finger type Dial Test Indicator (DTI) can be an invaluable instrument. It can also lead you down the "garden path" if you are not careful. I will discuss the limitations of a DTI plus how to test it for accuracy.Finger type Dial Test Indicators

By R. G. Sparber

Introduction

A reliable finger type Dial Test Indicator (DTI) can be an invaluable instrument. It can also lead you down the "garden path" if you are not careful. I will discuss the limitations of a DTI plus how to test it for accuracy.

A reliable finger type Dial Test Indicator (DTI) can be an invaluable instrument. It can also lead you down the "garden path" if you are not careful. I will discuss the limitations of a DTI plus how to test it for accuracy.

Recently I was truing my mill vise with my Starrett Last Word DTI. Ya gotta love a product with such a name. I set zero on the right side of the fixed jaw and was a bit surprised when, without any fiddling, the DTI read exactly zero on the left. Then I realized that the pointer stayed at zero after it was no longer in contact with the jaw. A little tap and it swung to its stop. Not a good sign. A second DTI showed that the vise was off by more than 15 thou. Time to send it in for repair.

What is a DTI good for?

There are many times when you want to know if two points are on the same axis. For example, when truing a vise, you want to know when the right top corner of the fixed jaw is at the same Y-axis location as the left top corner. When these corners are at the same Y value, the vise is parallel to the X-axis. In a similar fashion you can verify that your spindle is perpendicular to the Z-axis.

There are many times when you want to know if two points are on the same axis. For example, when truing a vise, you want to know when the right top corner of the fixed jaw is at the same Y-axis location as the left top corner. When these corners are at the same Y value, the vise is parallel to the X-axis. In a similar fashion you can verify that your spindle is perpendicular to the Z-axis.

Used in conjunction with a DRO, the DTI can tell you when you have precisely touched down on a surface. Then the DRO tells you the distance. You can trust the DTI when it reads zero.

These DTIs are also used to measure runout. The DTI is brought up to the side of a cylinder that can rotate. The DTI is then zeroed. As the cylinder is turned, you watch the DTI for a maximum positive and a maximum negative reading. This maximum swing is the Total Indicated Runout (TIR) and tells you how far off the center of the cylinder is from the center of rotation. If the cylinder is held in a 4-jaw chuck, it is a simple mater to reduce the TIR to zero if the cylinder is perfectly round.

What is a DTI

NOT good for?If you wish to measure the displacement of a surface, then the finger type DTI is not the best choice. The larger the displacement, the larger the error. In these cases, a push rod type DTI is the correct instrument.

How does a Finger type DTI work?

A finger type DTI actually measures angular displacement and not linear displacement. As the finger moves, it pivots around a central point. This rotation is geared to the pointer. My Starrett Last Word DTI dial shows a 15 thou movement as the pointer sweeps through 180 degrees. This means that the each tick mark is a rotation of 180 degrees/15 = 12 degrees.

There is a gear ratio between finger pivot and pointer rotation. A measure of my DTI finger reveals a length, f, of 300 thou. Say we move the tip of this finger 1 thou with a force perpendicular to the finger. We have a right triangle with hypotenuse of 300 and opposite side of 1. The resulting angle would therefore be the ASIN(1/300) = 0.19099 degrees. This 1 thou displacement moves the pointer to the first tick mark. Our gear ratio is therefore 12 degrees/0.19099 degrees = 62.832. This number will become handy as we look at error.

Key in the above calculation is the assumption that the force is perpendicular to the finger. This means that if the force is horizontal, the finger is vertical and that the pivot action is in the same plane as the force. The larger the deviation from this position, the larger the error.

Key in the above calculation is the assumption that the force is perpendicular to the finger. This means that if the force is horizontal, the finger is vertical and that the pivot action is in the same plane as the force. The larger the deviation from this position, the larger the error.

If we start out with a force, F, perpendicular to the finger and move a distance, d, say 1 thou, the error is not noticeable on the dial. Even at 15 thou, the angular displacement is 180.1 degrees rather than 180 degrees. That error cannot be read on my dial.

Now lets start with a force that is not perpendicular to the finger. The angle B will not be zero. Our force, F, moves the tip of the finger a distance d. The displacement error can be large. Say that B equals 45 degrees. The finger length, f, is still 300 thou. At a distance of 1 thou, the dial will read 1.4 thou. At d equal 5 thou the dial will read 7. Clearly you do not want to have the finger set this far from perpendicular if the goal is to read displacement. It is still fine for reading zero.

Now lets start with a force that is not perpendicular to the finger. The angle B will not be zero. Our force, F, moves the tip of the finger a distance d. The displacement error can be large. Say that B equals 45 degrees. The finger length, f, is still 300 thou. At a distance of 1 thou, the dial will read 1.4 thou. At d equal 5 thou the dial will read 7. Clearly you do not want to have the finger set this far from perpendicular if the goal is to read displacement. It is still fine for reading zero.

All is not lost. If you can be within 10 degrees of perpendicular, then at 5 thou the error is 0.1 thou. Below 3 thou of displacement the error is less than 0.1 thou. I have an Excel spreadsheet of these calculations. Contact me if you would like a copy.

The take home message here is that a finger type DTI is great for telling you when two surfaces are at the same position but is not so good at absolute accuracy. Those non-zero tick marks are only approximate. For best results, position the finger as close to perpendicular to the displacement force.

Testing a Finger type DTI

Even when you limit yourself to trusting the DTI only when it reads zero, you can still get in trouble. I did. In hindsight, I should have run the following two tests.

Test 1: repeatability of zero set

Does the DTI read the same value every time it hits the same surface? It should.

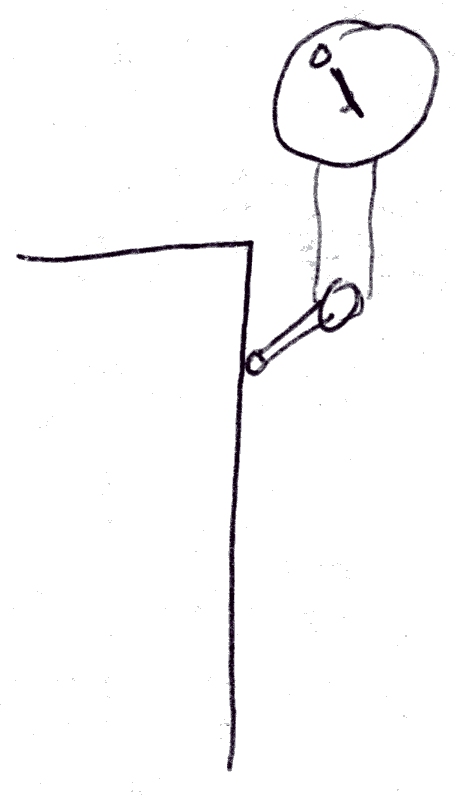

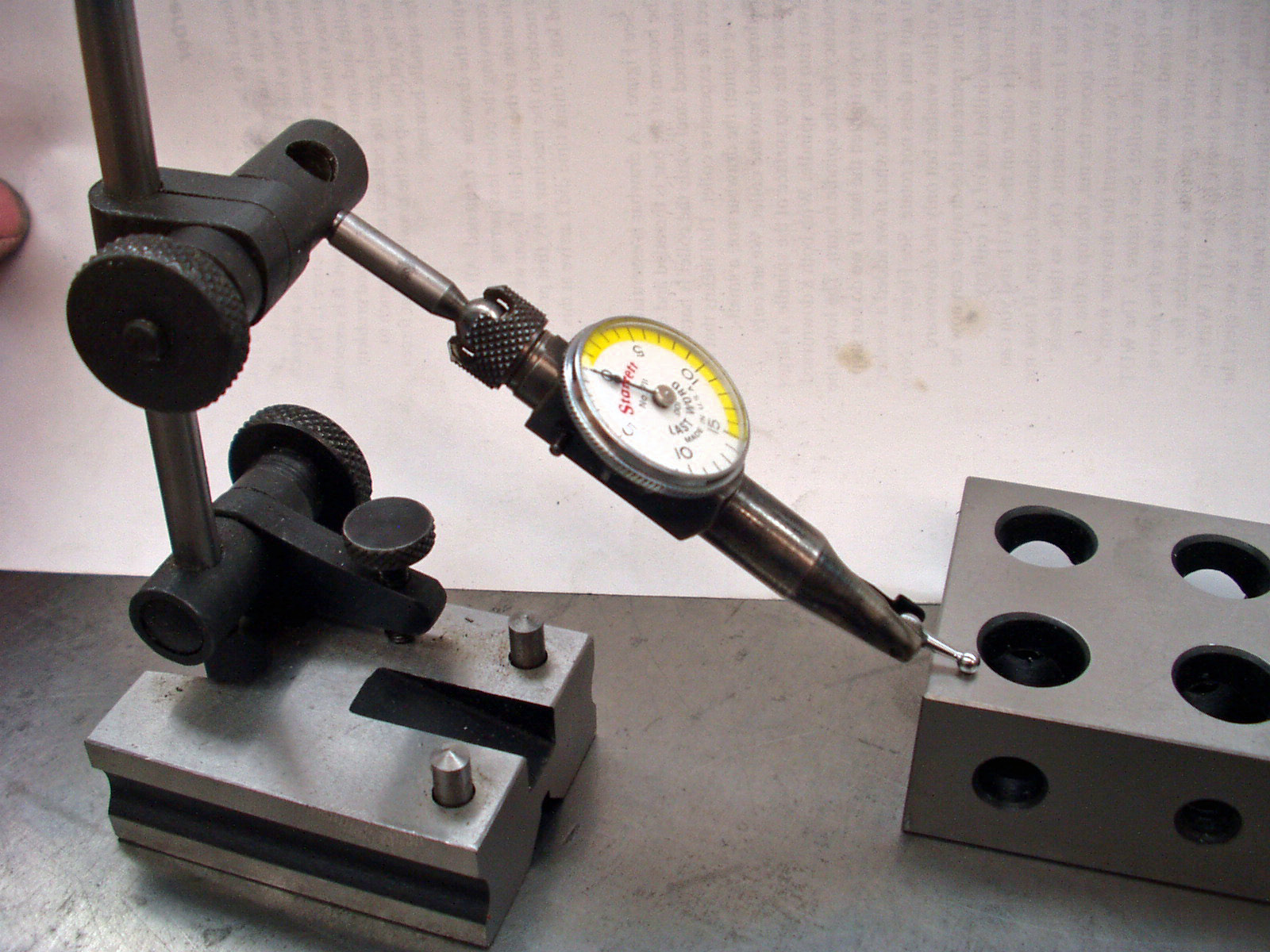

Set your DTI on a surface plate along with a square block. Lower the finger down on the block until you set zero on the DTI. With the DTI as shown above, move the base to the left. In this way the finger will experience no lateral force.

The DTI’s pointer should read zero every time it is on the block. If you see a shift, then your DTI may be in need of repair. My newly repaired Starrett had no noticeable shift. My Enco DTI, which has a tick mark every 0.5 thou was also solid. However, my garage sale super sensitive DTI could not stay within 2 thou of zero. Each tick mark is 0.1 thou. It is certainly not accurate but sure is precise (grin). So much for finding a bargain.

Test 2: linearity

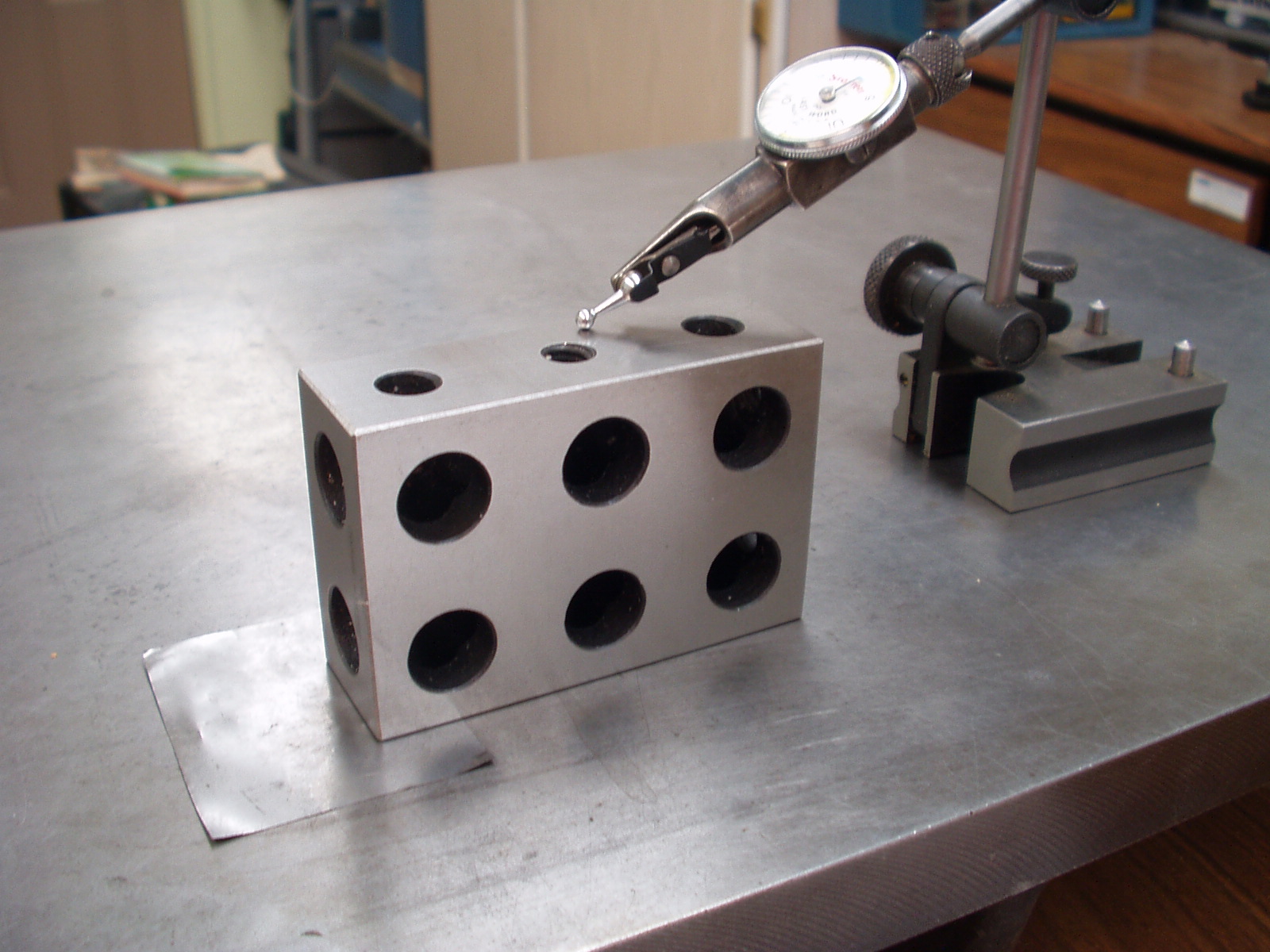

How smoothly does the DTI trace a surface? If it is the least bit sticky, you will get error. Again use the surface plate and block. A 5 thou shim is placed under one end of the block. Set zero on the DTI at the low end and then slowly move the DTI base towards the high end of the block. The dial should smoothly rotate. Once at the high end, slide back to the low end. If the dial moves in sudden jumps, it may be time for repair.

Acknowledgements

I would like to thank members of the mill_drill Yahoo group for their insights and corrections to this article. Together we are far smarter than any one of us.

I welcome questions and comments.

Enjoy!

Rick Sparber

November 6, 2006