return to home

page

|

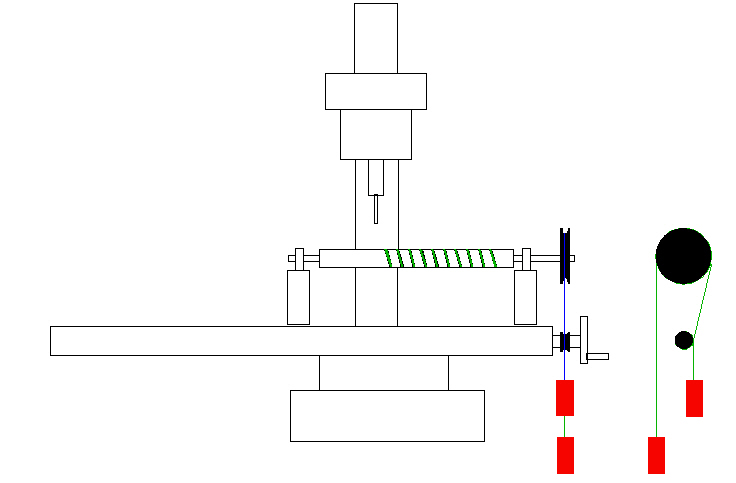

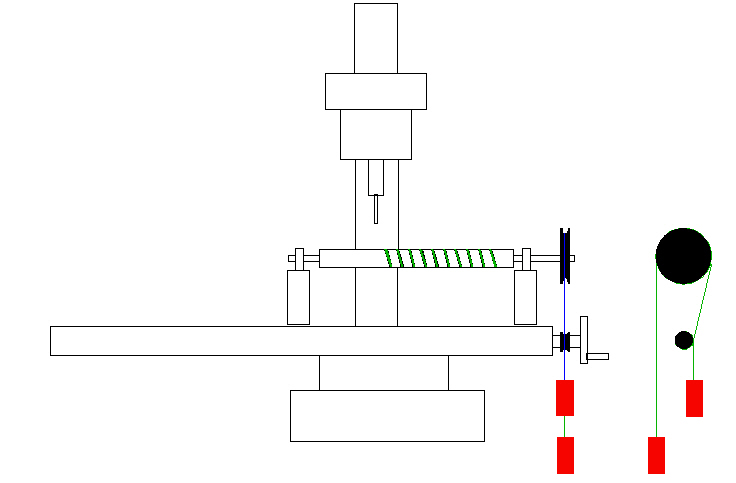

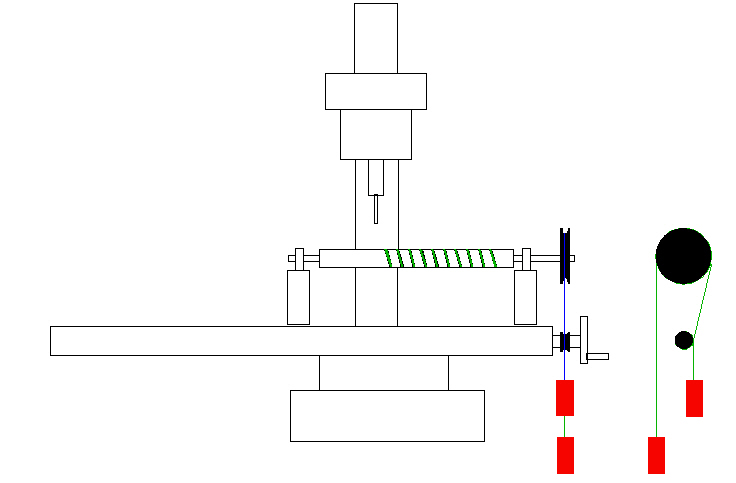

Cutting a Helix

with a Vertical Mill

|

|

Goal

|

I needed to cut a 1 thread per

inch helix 0.1" deep into round stock. I did not want to spend months

designing and building a fancy mill atachment. The design below is

cheep, VERY dirty, but works well. All parts were in my junk box.

|

|

Basic Idea

|

The round stock is linked to the

table feed with a 10 to 1 (thanks Tom) speed reduction. So as the table

feed wheel

turns ten revoltuions, the round stock turns one revolution. One

rev of the hand wheel advances the table 0.100" so ten revs of the hand

wheel advances the table 1" plus turns the round stock 1 rev. Now, here

is is "dirty" part: I wrap steel picture frame wire around both pulleys

and tension it with weights. This provides the gripping so the wheels

do not slip. The wire survives twice needed revolutions and then fails.

So each time I cut a helix into a fresh piece of round stock, I replace

the wire. I make the 0.1" deep cut in one pass.

|

|

|

| return to home

page |

last updated 01/15/2004

|